Understanding the different types of elevators is crucial for architects planning vertical transportation systems. This comprehensive guide covers hydraulic, traction, and machine room-less elevators with selection criteria, components, and code requirements essential for ARE exam success and professional practice.

This podcast is also available on YouTube, Spotify, and Apple Podcasts

You’re presenting your mid-rise apartment design when the client casually mentions they want to add 5 more stories. Suddenly, your hydraulic elevator choice just became a major problem.

Choosing the wrong elevator type can blow your budget, violate building codes, and create accessibility nightmares – not to mention trip you up on multiple ARE exam divisions. Mastering these systems is crucial for passing your architecture exams.

Here’s how to get it right from the start…

Understanding Elevator Types: The Foundation of Vertical Transportation

Elevators aren’t just about moving people up and down. They’re about creating accessibility, managing circulation flow, and sometimes even serving as the architectural centerpiece of a building. Ever been in one of those glass elevators in hotels? Sometimes they’re literally the visual star of the space!

Here’s why this matters for your ARE journey: elevator knowledge shows up across multiple exams – PA for programming, PPD for systems integration, and PDD for technical details.

The three main types of elevators:

- Hydraulic elevators – fluid-powered systems best for low-rise applications

- Traction elevators – cable and counterweight systems for taller buildings

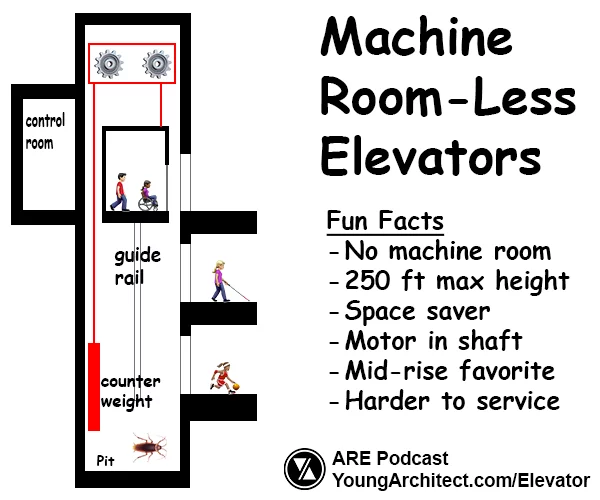

- Machine room-less (MRL) elevators – space-saving designs with elevator motor in the hoistway

Key selection factors include initial cost versus long-term operating costs, speed capabilities, maximum building height, traffic patterns, and energy efficiency goals.

Every building has unique needs, and choosing the wrong elevator system is like wearing flip-flops to climb Mount Everest – technically possible, but you’re going to regret it!

Essential Elevator Components Every Architect Should Know

Understanding elevator anatomy helps you plan space requirements and coordinate with other building systems like plumbing and MEP.

Structural and Moving Components

Key moving parts:

- Elevator cab – passenger compartment with customizable finishes

- Car sling – steel frame supporting the cab

- Guide rails – vertical tracks ensuring proper alignment

- Plunger (hydraulic only) – piston providing lifting force

- Elevator cables and counterweight (traction only) – balance system for efficiency

- Sheaves – grooved wheels moving the elevator cables

- Buffers – emergency shock absorbers at elevator pit bottom

The elevator counterweight system works like a see-saw – when one side goes down, it helps push the other side up, making the whole system more efficient.

Building Components

Space requirements:

- Elevator hoistway (shaft) – vertical travel space

- Elevator pit – space below lowest floor for safety and equipment

- Elevator machine room – separate space for elevator motor (except MRL systems)

All these components need to work together harmoniously – and they all take up valuable real estate in your building!

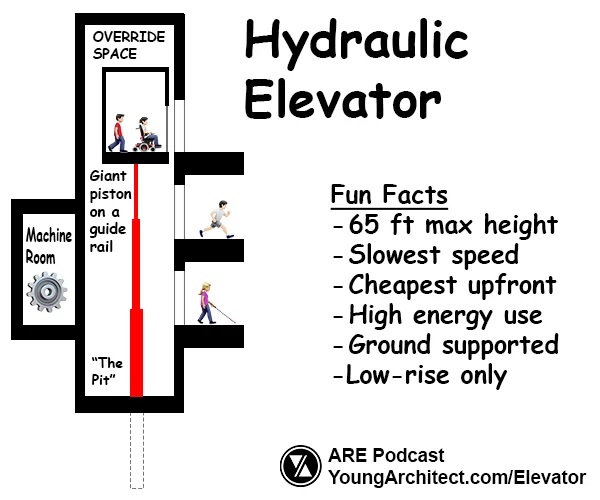

Hydraulic Elevators: The Low-Rise Workhorses

Hydraulic elevators are the workhorses of the elevator world – reliable and cost-effective for the right applications. Think of them like a pickup truck – powerful, practical, not fancy, but they get the job done for smaller loads and shorter distances.

Key specifications:

- Height limit: 65 feet (4-5 stories)

- Speed: Up to 200 feet per minute

- Cost: Most economical initial installation

- Energy: Higher operating costs over lifetime

Best applications:

- Low-rise buildings (offices, apartments, retail)

- Freight elevators and service elevators

- Theaters, parking garages, accessibility lifts

Advantages:

- Simple and compact design

- Load carried by ground, not building structure

- Less structural reinforcement needed

- Can be manually lowered during power failures

Disadvantages:

- High energy consumption

- Poor efficiency compared to traction systems

- Potential environmental concerns with fluid leaks

- Noise from pump and piping

Three main variants:

- Plunger-type – traditional design requiring deep shaft

- Hole-less – telescoping jack for difficult drilling conditions

- Roped hydraulic – hybrid approach combining hydraulic power with cables

If you’re designing a small building with just a few floors, hydraulic is often the way to go. Just remember to account for machine room space and consider long-term operating costs!

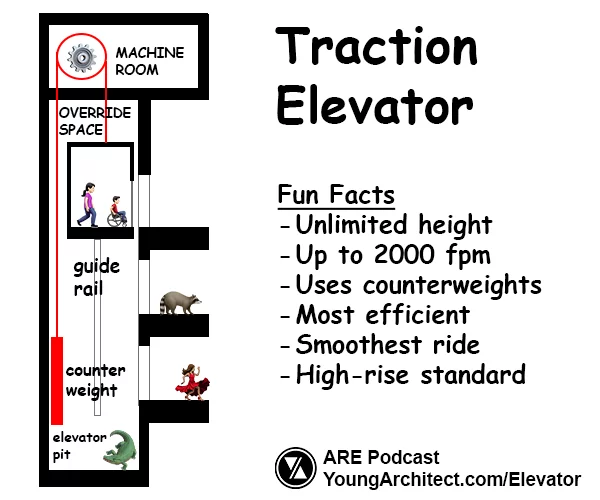

Traction Elevators: Power and Performance for Mid to High-Rise

Traction elevators come in two main varieties: geared and gearless systems.

Geared Traction Systems

Geared traction elevators are like a bicycle with multiple gears – they use mechanical advantage to balance speed and power.

Specifications:

- Height limit: Up to 300 feet (30 stories)

- Speed: 150-450 feet per minute

- Applications: Mid-rise buildings

Control types:

- Thyristor – medium cost, good performance

- VVVF – high performance, excellent control, higher cost

Gearless Traction Systems

Gearless traction elevators are like high-speed trains – designed for long distances at impressive speeds with smooth rides.

Specifications:

- Height limit: Unlimited

- Speed: Up to 2000 feet per minute

- Applications: High-rise buildings, luxury installations

Gearless traction elevators are the Ferraris of the elevator world – smooth, fast, and built for the long haul.

Advantages of traction systems:

- Better ride quality (smoother and quieter)

- Higher efficiency due to counterweight balance

- Longer lifespan than hydraulic systems

Disadvantages:

- Higher initial cost

- Greater structural requirements that vary by IBC construction types and fire ratings

- Building must support elevator system and counterweights

If your building is over five stories or you need faster speeds, traction is probably your best bet – just be prepared for that higher upfront cost!

Machine Room-Less (MRL) Elevators: Space-Saving Innovation

MRL elevators are the space-saving solution that building owners love. Think of MRLs as compact all-in-one printers – they pack all the functionality into a smaller footprint through clever integration.

How they work: Elevator motor mounted within the hoistway rather than in a separate elevator machine room.

Specifications:

- Height limit: Up to 250 feet (20-25 stories)

- Speed: Up to 500 feet per minute

- Cost: Medium to high initial costs

Biggest advantage: Space utilization – eliminates the penthouse machine room, reducing overall building height and freeing up roof space for other uses.

Considerations:

- Maintenance can be more complex due to confined equipment access

- Some jurisdictions have special requirements for control access

- Code requirements vary widely for these newer systems

If you’re working on a mid-rise project where space efficiency is a priority, MRL systems deserve serious consideration. Just verify local code requirements early in design!

Fire Safety and Emergency Protocols for Elevator Systems

This is where things get serious – we’re talking life safety here.

ADA Requirements:

- Minimum cab dimensions: 68″ deep x 80″ wide for commercial elevators

- Control panels at accessible heights with raised characters and Braille

- Audible signals and visual indicators required

Five-Step Fire Emergency Protocol:

When a fire alarm activates, elevators execute this mandatory sequence:

- Recall to designated floor (usually main exit level)

- Unlock and open doors upon arrival

- Disable call registration (elevator can’t be summoned)

- Deactivate control power (prevents normal operation)

- Enable firefighter’s service mode (emergency personnel control)

Key Code References:

- ASME A17.1/CSA B44 – Safety Code for Elevators and Escalators

- IBC Chapter 30 – Elevators and Conveying Systems

- NFPA 72 – Fire alarm interface requirements

This code knowledge impacts early design decisions and shows up on the PA exam! Master code navigation with our Building Codes 101 course. Consider space allocation, structural support, and emergency access and egress planning from the beginning.

Getting these elements right from the start saves massive headaches later and potentially saves lives in emergencies.

Common Elevator Design Mistakes and How to Avoid Them

Don’t be that architect who treats elevators as an afterthought! Here are the biggest mistakes that can derail your project:

Space Planning Errors:

- Underestimating shaft size, pit depth, and overhead clearance affects gross and net building area calculations

- Inadequate structural support planning

- Forgetting about machine room space requirements

- Insufficient lobby space for peak traffic times

System Selection Mistakes:

- Choosing hydraulic for buildings over 5 stories

- Mixing up speed capabilities between elevator types

- Overlooking emergency power requirements for fire service

- Not considering long-term energy costs

Coordination Challenges:

- Structural conflicts – some systems need top support, others bottom support

- Mechanical space battles – ductwork vs elevator shafts

- Electrical load miscalculations – elevators are power-hungry

- Poor planning for future modernization needs

ARE Exam Traps:

- Confusing MRL capabilities with traditional systems

- Forgetting fire safety protocol requirements

- Misunderstanding building height limitations for each type

Simple rule for the ARE: Hydraulic for low, traction for high, and always consider traffic flow!

Avoiding these issues requires good project management from the very beginning. Plan early, coordinate often through quality assurance and control processes, and don’t treat elevators as an afterthought!

Elevator Selection Guide: Choosing the Right Type for Your Project

Think of elevator selection like choosing the right vehicle for a road trip. You wouldn’t take a sports car camping or a moving truck to pick up groceries.

Building Height Decision Matrix:

- 1-4 stories: Hydraulic is usually most economical

- 5-20 stories: Consider geared traction or MRL systems

- 20+ stories: Gearless traction systems required

Other Key Factors:

Traffic Analysis: How many people need to move and when? Busy office buildings have different needs than low-traffic warehouses. Peak usage during morning and evening rushes dramatically affects system requirements.

Budget Planning: Consider both initial and lifecycle costs in your construction budget planning for hard and soft costs. Hydraulic might be cheaper upfront, but energy costs add up over decades.

Energy Efficiency: Traction systems with regenerative drives can feed power back into the building when descending.

Future Planning: Elevators need updates every 20-25 years. Planning for modernization from the beginning saves major headaches during project closeout and evaluation phases.

The key is matching your elevator choice to your building’s specific needs, not just going with what’s cheapest or what the contractor suggests.

Types of Elevators on the ARE Exam: What You Need to Know

Understanding elevators is crucial for passing multiple ARE divisions. Here’s how elevator knowledge shows up:

Programming & Analysis (PA):

- Early planning implications and cost considerations covered in our PA 101 course

- Space programming and budget allocations determined by building occupancy classifications and use groups

- Accessibility compliance requirements

- Initial programming decisions affect entire elevator design

Project Planning & Design (PPD):

- System selection criteria and capabilities covered comprehensively in our ARE 101 courses

- Integration with other building systems

- Understanding which system works for different building types and heights

Project Development & Documentation (PDD):

- Technical requirements and code compliance

- Coordination with structural systems

- Fire safety requirements and specifications

Key Study Tips:

- Create flashcards with elevator types, height limits, and speed capabilities as part of your realistic ARE study schedule and timeline

- Practice identifying appropriate systems for different building scenarios using multiple learning approaches and study methods

- Memorize the five-step fire safety protocol

- Understand ADA requirements for elevator accessibility

Common Exam Traps:

- Confusing MRL capabilities with traditional machine room systems

- Forgetting emergency power requirements for fire service

- Mixing up speed capabilities between different elevator types

- Not understanding relationship between building height and elevator type

Memory Device: Hydraulic for low, traction for high – that rule alone eliminates wrong answers quickly!

Ready to master this content? Our comprehensive courses include elevator system coverage with practice questions designed around NCARB’s exam objectives.

The Future of Elevator Technology

Now let’s take a quick peek into the future of elevator technology – because this field is changing rapidly!

One of the most exciting developments is destination dispatch systems. Instead of just pushing up or down, you select your floor before entering the elevator, and the system groups people going to similar floors. This dramatically improves efficiency in busy buildings.

Then there are rope-free elevator systems using magnetic levitation – similar to high-speed trains. The elevator of tomorrow might not use cables at all – magnetic levitation systems could revolutionize how we move through buildings.

We’re also seeing amazing advances in energy regeneration technologies. Modern elevators can actually generate electricity when they descend, feeding power back into the building! It’s like having a giant battery that also happens to move people around.

On the sustainability front, there’s a lot happening with energy recovery systems, standby mode optimizations that reduce power consumption when elevators aren’t in use, and materials innovations making elevator components lighter and more sustainable.

All these technologies will impact architectural practice in profound ways. Multiple cars in single shaft possibilities will change how we design elevator cores. Horizontal movement capabilities will allow elevators to go sideways as well as up and down – fundamentally changing how we think about building circulation. And reduced shaft space requirements will free up more usable area in our buildings.

The future of vertical transportation is arriving fast – and it’s going to change how we design buildings in exciting ways!

Conclusion: Mastering Elevator Systems for Success

Alright, we’ve covered a lot of ground – or should I say, a lot of vertical distance!

Here’s what you need to remember about the different types of elevators:

Hydraulic elevators are your economical workhorses for low-rise buildings up to 65 feet. They’re simple, compact, but have higher energy costs over time.

Traction elevators come in geared and gearless varieties. Geared systems work well for mid-rise buildings up to 300 feet, while gearless systems can handle unlimited height with superior performance.

Machine room-less (MRL) elevators save space by integrating machinery into the hoistway, perfect for mid-rise buildings where space efficiency matters.

Remember the fire safety protocols – that five-step emergency sequence could easily show up on your ARE exam. And don’t forget about ADA requirements and proper space planning.

Your elevator choices impact everything from the building structure to the user experience – getting it right from the start saves headaches later. Whether you’re studying for the ARE or designing your next building, understanding these systems is crucial for success.

Ready to master building systems and pass your ARE exams? Check out our ARE Bootcamp for comprehensive exam preparation with personalized guidance, or explore our ARE 101 courses for in-depth coverage of elevator systems and other critical building technologies.

Next time you’re riding in an elevator, take a moment to think about all the engineering and planning that went into making that smooth vertical journey possible. Pretty amazing when you think about it!